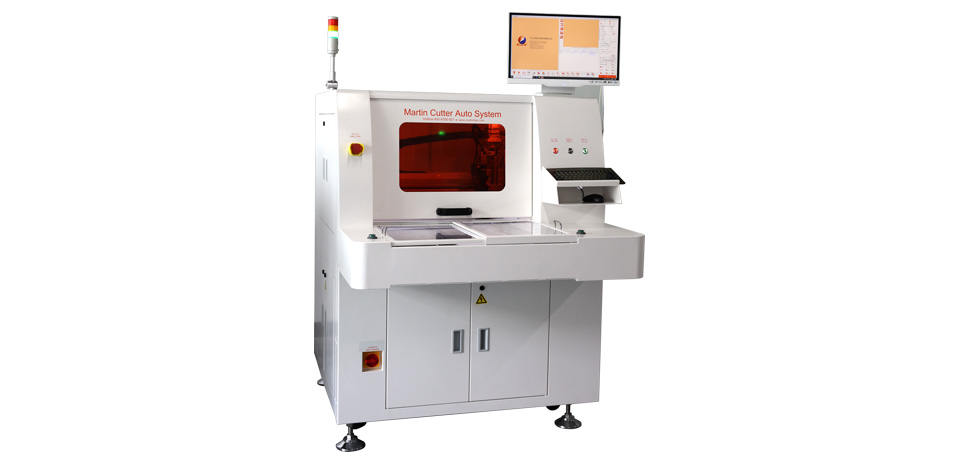

MT3000 Inline PCB Depaneling

Inline PCB Depaneling

A solution for low-stress depanelization, Martin Trier’s MT3000 is available in 3 models for different PCB sizes. With a quick learning method, the MT3000 uses the image taken with the CCD camera to create the cutting program. The cutting program can be loaded via the QR code on the PCB of fixture. The system is MES ready and a special kit for aluminum PCB depanelinng is available.

Features:

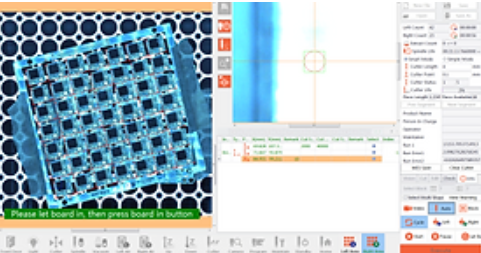

Image Orientation Programming

The PCB is scanned by a CCD camera and the fiducial mark and cutting path are taught on the PCB image.

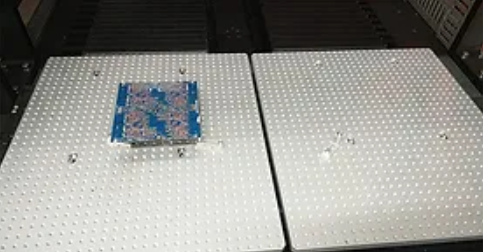

Dual Table

Dual table can minimize the idle time. When one table is routing, the other table can exchange the PCB.

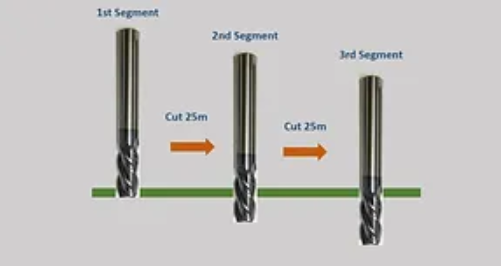

Intelligent Cutting Mode

The cutter is divided into several segments. When one segment reaches the cutting distance limit, it switches to another segment to continue thus, increasing the lifetime of cutting bit.

Main Features

- Solution for Low Stress Depaneliztion

- A quick and easy method to learn and use by image orientation programming

- Automatic Alignment Compensation by CCD camera

- Milling Cutter intelligent mode

- Whole process monitoring on the operation error

- Read PCB or Fixture QR code load program

- MES Ready

Key Specifications:

- PCB Size: Standard 300x350mm

- Routing Mode: Straight Line, Curve, Arc

- Work Mode: Inline Dual Table

- MAX BCP Thickness 3mm

- Repeatability +/- 0.02mm

- Spindle Speed: 60000 rpm

- X Y cutting Speed: 0-100 m/s

- Cutting Diameter 0.8-3.0mm

- Vacuum Cleaner: Uper or lower

- Air Supply Source: 0.5Mpa

- Dims: 2160x1150x1700mm

- Weight: 900kg

![]()

![]()

![]()