Scienscope X-Ray Systems

The cabinet style advanced micro-focus X-Ray product line from Scienscope today gives our customers a very efficient design. Our ratio of floor space to inspection area is remarkable, and yet, with such compact design the systems are very accessible for easy part loading. We listen to our customers requirements and build efficient cost affective machines for real-world applications. From the single sample lab environment to the production floor Scienscope builds a variety of machines to cover your needs.

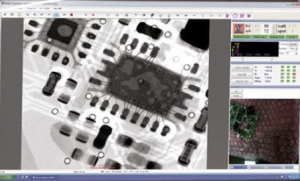

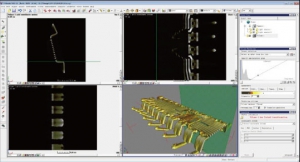

Xspection 6000 Microfocus System

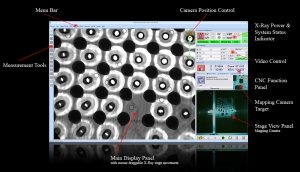

The Xspection 6000 is a Digital fully programmable CNC controlled x-ray inspection system that allows operators to program inspection and measurement routines with point and click ease.

Standard features include;

Standard features include;

- A 2″ x 2″ Digital Flat Panel X-ray detector with 2000 x 2000 pixel resolution

- 130 kV- 3 micron x-ray tube,

- independent Z axis movement of the x-ray tube and image detector

- variable speed X-Y stage with 70 degree tilting of the x-ray tube and x-ray detector

- a full featured CNC programmable image processing / measurement CPU with 24” LCD flat panel monitor.

Typical applications include

Typical applications include

- multilayer PCBs

- inner layer registration

- through hole plating inspection

- semi conductor inspection

- fine pitch solder joint integrity

- BGA – micro BGA – flip chip inspection

- encapsulated components

- BGA – SMT rework verification and failure analysis

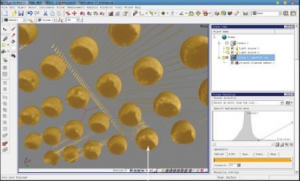

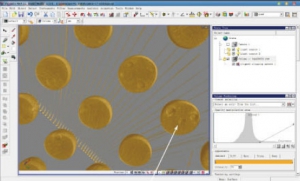

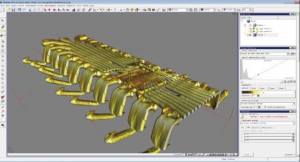

With the optional full CT Software the system offers full 3D CT capabilities. Below some examples.

X-Scope 1000

The X-Scope 1000 is a smaller, less costly high resolution x-ray inspection system designed for batch inspection.

Standard features of the X-Scope 1000 X-Ray Inspection System

- A 2”x2” digital flat panel x-ray detector

- 90 kV- 7 micron x ray tube

- Z axis movement of the x-ray tube and sample stage

- Computer controlled kV and mA settings

- Computer controlled variable speed X-Y stage

- Full featured Image processing CPU with 17 inch LCD flat panel monitor

- Optional 360 degree sample stage rotation available

Applications

- Inspection of over molded electrical connectors

- Encapsulated components

- Aluminum die castings

- Molded plastic components

- Ceramics

- Aerospace components

- Electrical / mechanical components

- Electronic components

- SMT assemblies

- Pharmaceuticals

- Automotive assemblies

- Agriculture

- Counterfeit inspection

- Cell phone battery inspection

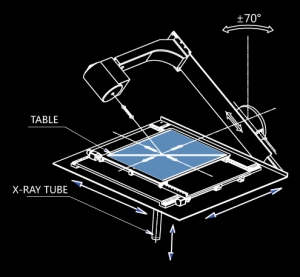

X-Scope 1800

The X-SCOPE 1800 is the new addition to the X-SCOPE Series inspection systems featuring wide inspection area with tilting X-Ray tube and detector capability.

Standard features of the X-Scope 1800 X-Ray Inspection System

Standard features of the X-Scope 1800 X-Ray Inspection System

- A 2”x2” digital flat panel x-ray detector

- 90 kV- 5 micron x ray tube

- Z axis movement of the x-ray tube

- Computer controlled kV and mA settings

- Computer controlled variable speed X-Y stage

- Full featured Image processing CPU with 19 inch LCD flat panel monitor

- 70 degree tilting tube and detector

Applications

- BGA Inspection

- Inspection of over molded electrical connectors

- Encapsulated components

- Aluminum die castings

- Molded plastic components

- Ceramics

- Aerospace components

- Electrical / mechanical components

- Electronic components

- Pharmaceuticals

- Automotive assemblies

- Agriculture

- Counterfeit inspection

- Cell phone battery inspection

X-Scope 2000/2300

The X-Scope 2000 series is a general purpose, high resolution, fully programmable x-ray system designed to address the nondestructive testing needs for failure analysis, research and development, process development, process monitoring and the ongoing support of electronics assembly, rework and repair.

The X-Scope 2000 is a “batch” or manual type of x-ray system and includes a Windows based workstation (Capture X 2000) with multiple image processing functions for real time measurement and data collection. The X-Scope 2000 has an unbeatable price to performance ratio and many advanced features you would expect to find on a much more expensive x-ray imaging system.

Scienscope has combined ease of use, excellent image quality and low price in the development and introduction of the X-Scope 2000.

Standard features of the X-Scope 2000/2300 X-Ray Inspection System

Standard features of the X-Scope 2000/2300 X-Ray Inspection System

- 4/2 dual field image intensifier with mega pixel camera (2”x2” Flat Panel Dectector Optional)

- 90 kV- 5 micron x-ray tube

- Z axis programmable computer controlled movement of the x-ray tube and image detector

- Computer controlled programmable kV and mA settings

- Programmable computer controlled – variable speed X-Y stage with a 75 degree sample tilt fixture

- Full featured image processing CPU with 22 inch LCD flat panel monitor

- Look down (Birdseye view) stage camera

Applications

Applications

- BGA Inspection

- Inspection of over molded electrical connectors

- Encapsulated components

- Aluminum die castings

- Molded plastic components

- Ceramics

- Aerospace components

- Electrical / mechanical components

- Electronic components

- Pharmaceuticals

- Automotive assemblies

- Agriculture

- Counterfeit inspection

- Cell phone battery inspection