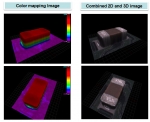

Combined 2D and 3D inspection. 3D OMNI-Vision

The MV-9 series is the first In-Line 2D/3D AOI which utilizes a 15 Mega Camera, 4 way Multi-Frequency 3D Moiré technology and a linear motor system.

With simultaneous 2D/3D tests in one head highest productivity is achieved and falls calls are avoided.

Advantages of the 2D/3D inspection

• Achieve ZERO false call by 2D/3D concurrent inspection

• Complete 3D measurement (height, area, tilt, lift, etc.)

• Complete soldering inspection by 6 Phase colour lighting system

• Detect side defects with 10 Mega Side Viewer®

• Non-distortion during image magnification

• Applied 1µm high precision linear motor

The 2D inspection happens with the approved advanced 15 Mega Pixel digital colour camera technology and high

resolution telecentric lens. This technology provides the ultimate inspection performance and speed. The optional Side Viewer® Camera System provides enhanced inspection capability through the addition of

four Ten Mega Pixel Side View Digital Colour Cameras.

Inspection Performance 2D

• High resolution digital 15 Megapixel colour camera and telecentric lens

• Fast PCB inspection: up to 83 cm²/sec

• MIRTEC’s innovative Quad Angle Lighting System for an enhanced solder joint and solder bridge inspection capability

• The optional 10 MP side Viewer® Camera System for an enhanced detection of complex components.

• Three stage conveyor system with automatic board support and PCB clamping mechanism is designed for

maximum throughput of the line

• Precision motion control systems provide absolute reproducibility and repeatability.

• Powerful OCR Engine provides advanced part marking inspection

By changing the magnification of the Precision Telecentric Lens the resolution of optics system may be scaled from 20 microns/pixel with an incredibly large FOV of (77.7mm x 77.7mm) desired for extremely high speed manufacturing; down to 10 microns/pixel with an FOV of approximately (38.8mm x 38.8mm) which is suitable for high end micro-electronics manufacturing.

MIRTEC’s revolutionary 3D Multi Frequency Quad Moiré Technology, provides true 3D inspection of SMT devices on finished PCB assemblies using a total of four (4) Moiré Inspection Probes. This proprietary system yields precise height measurement used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-7 machines will also feature four 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.

MIRTEC’s revolutionary 3D Multi Frequency Quad Moiré Technology, provides true 3D inspection of SMT devices on finished PCB assemblies using a total of four (4) Moiré Inspection Probes. This proprietary system yields precise height measurement used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-7 machines will also feature four 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.

Downloads:

| Item | Description | Download |

|

Mirtec MV-7Xi In-Line AOI System | |

|

Mirtec MV-7Xi In-Line AOI System | |

|

Mirtec Angled Lighting Brochure | |

|

Mirtec Intelli Beam Feature | |

|

Mirtec Intelli Scan Feature | |

|

Mirtec Telecentric Lens Feature | |

|

Mirtec Angled Camera’s Features | |

|

Mirtec Resistor Check Feature | |

|

Mirtec Lens options |